|

| Back side of cured part for side panels. |

Vacuum bagging of the instrument side panel material was a success however the part compressed more than we thought it would so we didn't achieve the desired thickness necessary to surface match to the center panel. That's ok. A small lip down from the center panel to the side panels still works. One would think 8 layers of cloth would make for a thick part. Eight hours of -28InHg vacuum really bleeds all excess resin resulting in a very nice 50:50 fabric to resin ratio for the part.

Left and right side panels were cut to exactly match the aluminum back plate. This required a lot of careful cut, fit, sand, repeat. The holes for the AOA, ELT, and side vents will be cut after clear coating.

|

Center and side panels were scuff and cleaned. Wax & Grease remover was used as a final cleaner to ensure that all contaminants were removed prior to painting.

Master painter, John Branchaw, carefully applied four layers of clear coat to each panel.

|

| Finished carbon fiber panel. |

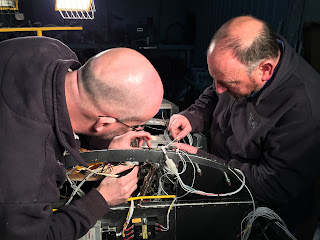

Next step, mount the avionics trays and install the avionics.